For sealing ascending screw conveyors for light to very abrasive products, we have developed a new seal, the CinchSeal NVB Series for shaft sizes from 20 mm to 80 mm. The seals always have a wear resistant 304 stainless steel end plate that is installed against the machine flange and have a 304 stainless steel (left), hard coated aluminum (middle) or anodized aluminum (right) housing.

The seals are equipped with a wide heavy duty elastomer, which has a larger contact surface with the shaft and can optionally be fitted with a hose clamp. The two wide heavy-duty Rotor Cups are extremely sturdy, wear-resistant and offer a larger sealing surface. As a result, these seals can also be used on ascending screw conveyors and wherever a seal is subject to heavy loads.

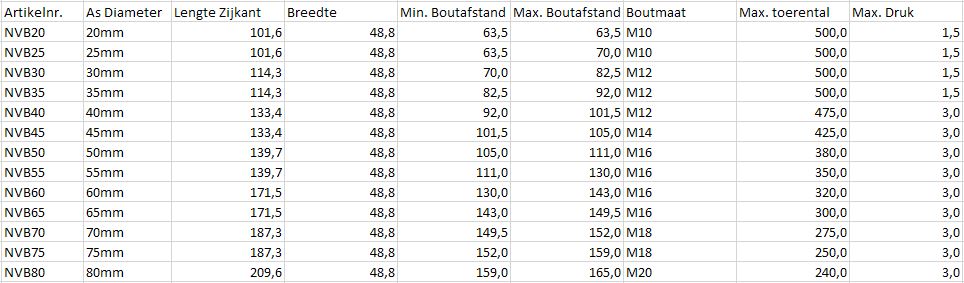

The housing and hole pattern are adapted to standard SKF square block bearings, which can be mounted directly against the seal. The housings come in standard sizes but a custom design is always possible. An overview of the technical data can be found at the bottom of the page.

These seals are an ideal and proven solution for transporting or processing bulk materials, (abrasive) foodstuffs, chemical products, but also semi-solids, slurries and liquids. For example, we have already successfully applied all three NVB seal models in many industries and have therefore been able to increase the production value for many customers.

For more information about this sealing model, please contact us !